we all love

accuracy

TACCO project makes easier and more accurate the setting up process for big and heavy parts

Project Objectives

TACCO Project aims at developing a groundbreaking innovation for the fast, reliable and accurate setting-up of raw parts using an attractive, flexible and easy-to-use modular approach based on photogrammetry, enabling the democratic engagement of one-of-a-kind operators to a critical manufacturing process step, the raw part set-up, which still remains kidnapped and limited to experienced operators and specialized tools.

Key Motivation

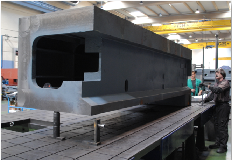

Manufacturing of high-added-value large components (aeronautics, railways, capital goods, etc.), usually requires:

- Alignment of large raw parts prior to their machining: key process for Zero-Defect manufacturing

- Productivity loss (up to 20-25% of total machining time) due to:

- Long time-consuming processes (mostly manual)

- Labour intensive and strongly dependant on skilled operators using specialized measuring instruments (e.g.: laser-trackers) and metrological software

- Lack of fast, reliable and accurate democratized solution for raw part set-up, available for one-of-a-kind operators and based on attractive technology.

Heavy parts

Manual process and traditional means.

Laser based systems

Expensive and generic measurement instruments

Big machines

Idle times due to in machine raw part set-up

Expected Impact

QUESTIONS?

Whether you’re curious about features, a free trial, or even press, we’re here to answer any questions.

«Co-funded by the EIT Manufacturing and the European Commission. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the EIT Manufactuing nor the European Union or the European Health and Digital Executive Agency (HADEA).»